Socket weld fittings refers to a pipe inserted in to a recessed area another pipe or fittings. It is using seal welding process as they are usually in small dimensions below 2 inch. Manufacturing standards complied to ASME B16.11. Material also in carbon, alloy and stainless steel.

How many ways to connect pipes and fittings

Normally there are four ways to connect pipes and fittings: socket weld, butt weld, threaded, and flanged. In practical applications the following two types of connecting ways are popular: socket weld and butt weld.

Usage of socket weld fittings

Socket weld pipe fittings normally used in high pressure pipeline systems in different industries as below:

• Oil and Gas, petrochemicals.

• Medical science.

• Power stations of electric or nuclear.

• Environment control.

• Aerospace constructions.

• Fire protection systems.

• Mining slurry.

• Shipbuilding.

These industries normally required for higher precision parts and high pressures.

Types of Socket Welded Pipe Fittings

Like butt weld fittings, socked weld pipe fittings also ranged in elbow, tee, cap, reducer, more over includes couplings (full coupling, half coupling, reducing coupling), Reducing insert (Types 1, 2 and 3), socket welded union.

Material also ranges in carbon steel, alloy steel and stainless steel.

Carbon steel socket weld fittings

Standard: ASTM A234 WPB, WPC, ASTM A105

Alloy Steel SW fittings

Standard: ASTM A234 WP5, WP9, WP11, WP22, WP91

Stainless steel socket weld fittings

Standard: ASTM A403 WP304/304L, WP316/316L, ASTM A182, and Duplex material

Below we will explain by each type.

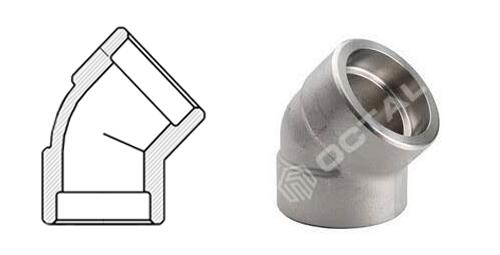

Socket Weld Elbow

Socket Weld Pipe Elbow also called SW Elbow, it has 45 degree and 90 degree types. Manufacturing by forging process and also ranges in long radius (LR with 1.5 X OD) and short radius (SR with 1 X 0D) model, it has been a common socket weld fittings that used in the pipelines for changing the fluid directions.

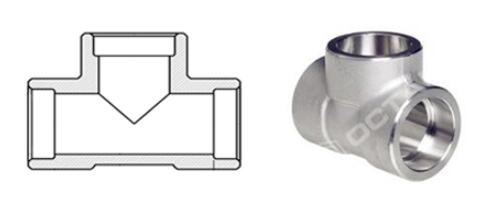

Socket Weld Tee

Also Ranges in Straight Tee and Reducing Tee.

Socket weld tee is to make a 90 degree branch from the main run of the pipe.

Socket weld reducing tee is with a smaller diameter branch which connecting the smaller pipe branch.

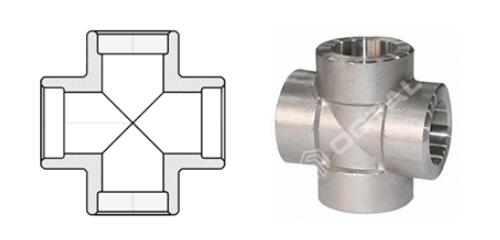

Socket Weld Cross

Socket weld cross functioned to make three 90 degree branches from the main pipeline.

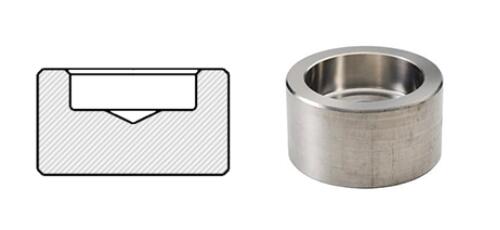

Socket Weld Cap

Socket weld cap is to seal the pipe end.

Socket weld coupling ranges Full Coupling, Half Coupling, Reducing Coupling.

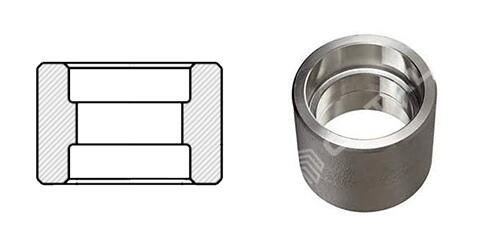

Full Coupling

Socket weld full coupling is to joint two pipes with welding process.

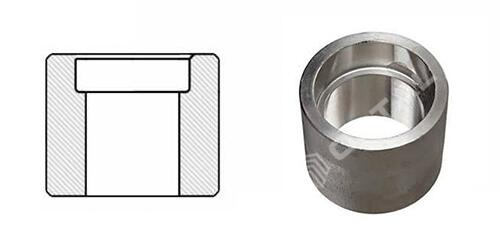

Half Coupling

Half coupling is socket welding in one end, butt welding for another end.

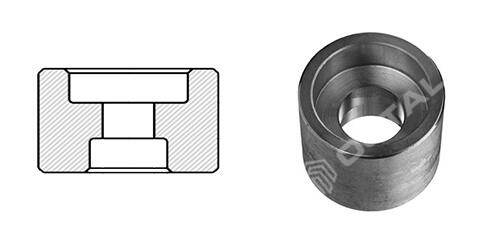

Reducing Coupling

Reducing coupling is to do socket welding for two different diameter pipes.

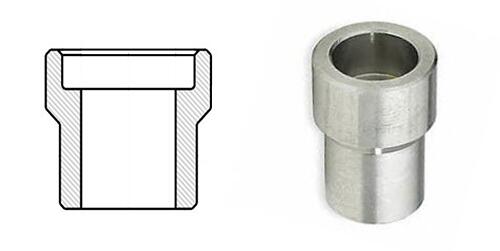

Reducing Insert

With reducing insert you can insert to another socket weld pipe or fittings, it provides different combinations for to quick connect with different diameter pipelines.

Socket Weld Union

Socket weld union includes a screwed joint in the middle to connect three parts as you can see in above photo, with the internal threads will draw two ends together. It shall be noted that before do the socket welding, you have to screw it to tight the three parts firstly. This will minimize the warping of the seats.

Sockolet is a typical olet in the socket weld fittings, same with the weldolet and threadolet, sockolet is using to weld a small diameter pipe to a big dia pipe. Compared to other type olets, it offers a precisely 90 degree direction turning and better strength to bear higher pressure.

During installation, sockolet one bore connected with outlet bore, another bore in a span and oval shape to stable the sockolet sit on the bigger pipe. So it's function is similar to reducer tee, and during some cases it can replace tee completely, save much cost and very convenient to use. Especially in large diameter pipelines bigger wall thickness with higher temperature, higher pressure requirements.

Referred standards MSS SP97, pressure ratings 3000#, 6000#.

Socket Weld Flange

Socket weld flange also called SW flange, the flange has a recessed shoulder at the inner bore, to insert the pipe to this recessed area and connect with welding work. This welding structural is more compatible with small pipeline and providing a smooth bore and great transmission for liquid.

SW Flange also has several sealing types like RF (Raised Face), FF (Flat Face), RTJ (Ring Tenon Joint), pressure ranges 150#, 300#, 600#, 1500# and up to 2500#.

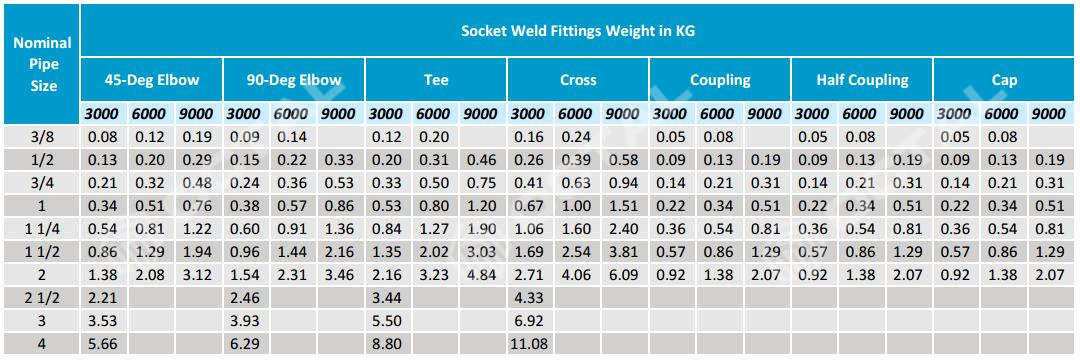

SW Fittings Weight according to ASME B16.11

Advantages and Disadvantages for SW Fittings

Advantages

1. The pipe is no need beveling for preparation of weld.

2. The welding position can adjust to flat welding.

3. Generally no need temporary tack welding for alignment. This is because the fitting principle helps to ensure that the alignment is correct.

4. The socket weld metal is not be able to penetrate the bore of the pipe.

5. It has found that socket welding is more economical than butt welding. Due to elimination of special machines and reducing precision assembly requirements.

Disadvantages

1. The welder should be aware that there is an expansion gap about 1.6mm between the shoulder of the socket and the pipe.

2. Internal cracks and expansion gaps in the socket welding system promote corrosion. This reason make them considered as less suitable for radio-active or corrosive applications.

3. These types of accessories are also unacceptable for ultra-high hydro-static pressures in the food industry. This is because, in addition to not allowing complete penetration, it leaves cracks and gaps which can become very difficult to clean.

Considering above reasons, butt weld fittings have better pressure resistance and higher connecting strength.

Octal supplies Socket Weld Pipe Fittings with competitive price and urgent delivery.

Material standard ASTM A105, ASTM A182, dimensions up to 4 inch.