6D Bend is a long radius bend, which bend radius 6 times of the pipe OD (distance between bend circle center and bend centerline center 6xOD), for example a 10 inch of 6D bend the radius will be 60inch.

Long Radius Bend

Long radius bend also named LR bend, it includes the bend radius more than 1.5D, so 6D bend is long radius bend. Below 1.5D usually called elbow, shore radius elbow refers the elbow radius in 1D.

Bending Radius:

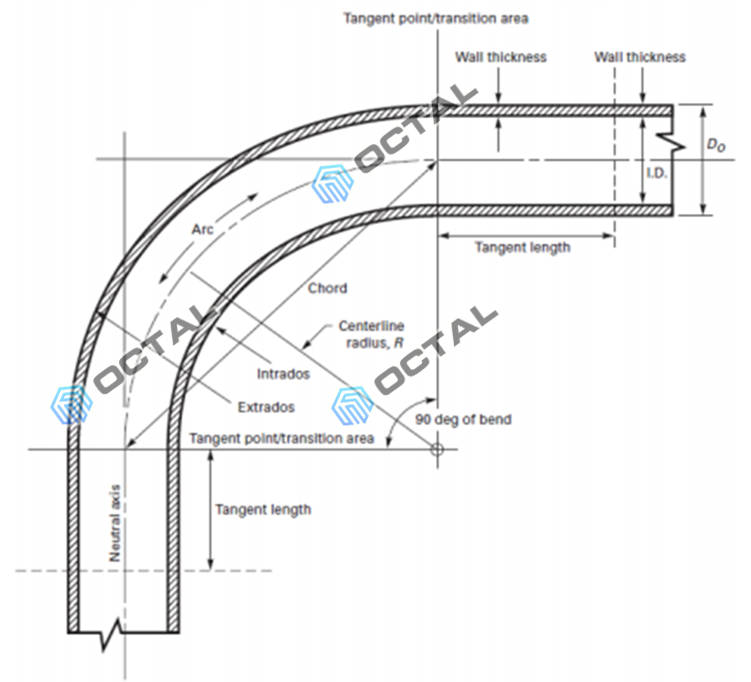

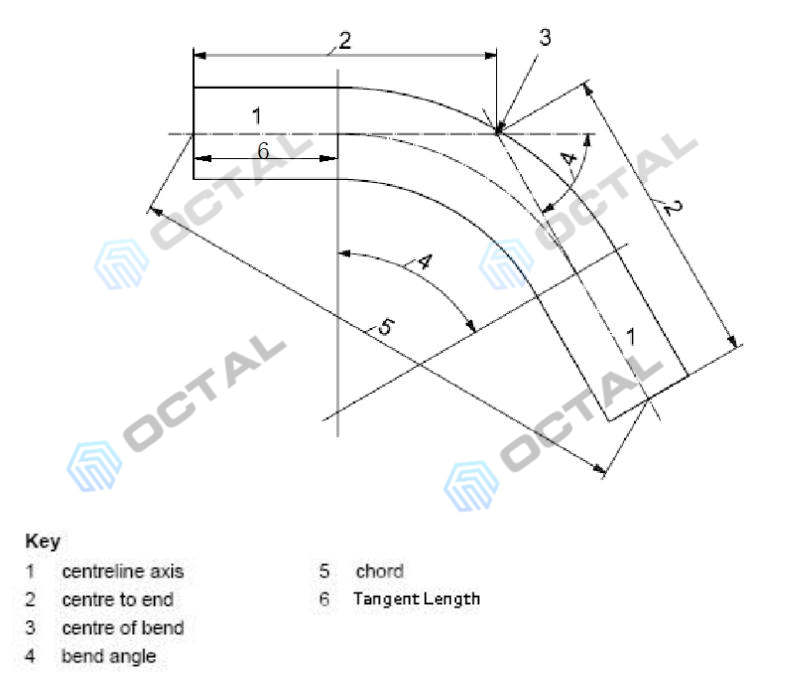

Like below pictures 90 degree of bend radius defined by the intersection of two lines from the bend end, exclude the tangent length part (strait pipe part), which looks like a quater of circle. Between the circle center and the centerline center is the centralized radius, also named CRL. CRL is specified as the multiple of pipe outer diameter, as 3D bend, 5D bend, 6D bend, 8D, 10D and over.

Bend Length

Bend length is related with bend angle, for example a 90 degree bend length 5 meters (like 16 inch bend), then the 45 degree bend length is 2.5 meters (half of 90° length), and 30° bend length 1.5 meters (1/3 of 90 degree bend).

Tangent Length (Straight Pipe Length)

Tangent length means the straight pipe part length on two ends of the bend, add tangent length or not is an option for the pipe bend, to save the material some client will remove the tangent, it has the same function to change pipeline direction with or without tangent length.

On the other hand, adding the tangent length will make welding work more easy when connecting the pipe with the bend.

Usually the tangent length is 500mm or could customized by client.

6D Bend Manufacturing Process

There are hot induction (hot forming) and cold forming for manufacturing pipe bend. In most cases applied with hot forming, and cold forming only used for making small pipe bend below than 2 inch.

Hot Forming / Hot Induction

Bending machine composites with hydrostatic pusher, heating rings, water cooling system, lever arm (To lock the radius), stablizer arm as below pictures:

Hot Induction / Hoting Forming to manufacture Long Radius Bend / 6D bend

Procedures:

a. Install the raw pipe on the hydrostaic pusher.

b. Move the pusher to locate the pipe to the certain postion. (Induction start position)

c. Heat the pipe and meanwhile pushing the pipe forward.

d. Use lever arm to lock the pipe to the certain radius, the pipe will follw the lever arm to form the required radius.

e. Cooling the pipe with the water.

Heat Treatment for High Strength Material

The whole production process for making the bend could be considered as a hot forming and quenching processes, so the finished bend stress and hardness will increase during this procedures. To get a qualified bend, a proper heat treatment (annealing) shall be done for the inside stress relieve and reduce the hardness. Especially for the high grade high strength material.

Test required

Ultrosonic test is mandatory.

X-Ray test could be done as buyer and manufactuer agreed.

Magnetic test (Optional if UT has done).

Hydrostatic test optional, hydrostatic test will break the bend normally, so usually one piece test will be enough.

Hardness test is mandatory.

Guided bend test optional.

Tensile test and chemical test.

6D Bend Material Standard and Grade:

Normally the pipe bend material standard applied same with buttweld pipe fittings standard as follow:

ASTM A234WPB, WPC, WP5, WP9, WP11, WP22,WP91

ASTM A860 WPHY 42, 52, 56, 60, 65, 70

MSS SP-75

ASTM A420 WPL6

ASTM A406 WP304, 316

Or some times also expressed with pipe standard like:

ASTM A106B, A53B

API 5L B, X42, X46, X52, X60, X65, X70

ASTM A333 Grade 6

ASTM A335 P5, P9, P11, P22, P91

ASTM A312 WP304, WP316

Coatings

Coating types for bend:

3LPE external coated

Epoxy painting Internal or external

FBE Coating

Clad and lined

Anti-rust painting

PE Coating & Wrapping