ASTM A403 Stainless Steel Pipe Fittings refers to the material of forged and rolled austenitic stainless fittings for pressure pipes. Common grades are WP304/L, WP316/L. They can be used into many fields as engineering industry, energy conversion plants etc.

ASTM A403 Standard Scope

The standard includes several grades of austenitic stainless steel alloys, and uses the WP or CR prefix to mark the grade of steel, depending on the applicable ASTM or MSS size and rated pressure standards.

ASTM A403 is designed for forged steel pipe fittings, Cast pipe fittings are not suitable. (Austenitic stainless steel castings are included in these standard, A351/A351M, A743/A743M and A744/A744M.)

WP Grade Stainless Steel Pipe Fittings

Material under this standard named as WP Grade, and for each WP grade stainless steel, several categories of pipe fittings are included, to indicate that a seamless or welded structure is used. Class designations are also used to indicate non-destructive testing methods and the extent of non-destructive testing (NDE).

Units of Description

This standard and applicable material standards are described in both inch-pound units and SI units. However, unless the "M" standard number (SI unit) is specified in the order, the material is supplied in inch-pound units.

Values expressed in either inches-pounds or SI units should be considered standard values. In the text, SI units are shown in brackets. Since the values in the two unit systems are unlikely to be exactly equal, it is necessary to independently adopt two unit systems. If mixed, it will lead to inconsistency with this standard.

Referred Standards of ASTM A403 SS Pipe Fittings

• ASTM A351/A351M: Casting, Austenitic, for Pressure-Containing Parts Specifications

• ASTM A743/A743M: Specifications of Casting, Inron-Chromium, Iron-Chromium-Nickel, Corrosion Resistant for General Application

• ASTM A744/A744M: For Server Service other than A743M (for the same material)

• ASTM A751: Test methods, Practices, and Terminology for Chemical Analysis of Steel Products.

• ASTM A960/A960M: Specifications for Common Requirements of Wrought Steel Pipe Fittings.

• E112: Test Methods for Determining Average Grain Size

• E165: Practice for Liquid Penetrant Examination for General Industry

• ASME B16.9: Factory-Made Wrought Steel Butt Weld Fittings

• ASME B16.11: Forged Steel Fittings, Socket Weld and Threaded

• MSS SP-25: Standard Marking System for Valves, Fittings, Flanges, and Unions

• MSS SP-43: Standard Practice for Light Weight Stainless Steel Butt Weld Fittings

• MSS SP-79: Socket Weld Reducer Inserts

• MSS SP-95: Swaged Nipples and Bull Plugs

• MSS SP-97 Integrally Reinforced Forged Branch Outlet Fittings of Socket Weld, Threaded

• AWS standard of A 5.4, A 5.9, A 5.11, A 5.14.

Our Supply Range

Specification: ASTM A403

Grades: WP304, WP304L, WP310S, WP316, WP316L etc.

Types: seamless or welded

Dimension Range: 1/2" NB to 48" NB

Wall Thickness Range: Schedule 10s, Schedule 40s, Schedule 80s

Fitting Types Covered in A403 Standard

Material

The material used for the pipe fittings shall be the forgings, bars, plates, seamless or welded tubular products specified in the chemical composition table.

Smelting

Steel should be smelted using one of the following methods:

a. Electric furnace (with separate and refining optional)

b. Vacuum furnace

c. One of the former followed by vacuum remelting or electroslag- consumable electrode remelting

d. If secondary melting are used, the furnace number refers to all steel ingots remelted with one smelting furnace number.

Manufacture

Forming

The forging or forming operation may be performed by hammer forging, press forging, perforating, extrusion, upsetting, rolling, bending, welding or machining, or two or more methods at the same time. The forming process should ensure that no harmful defects are produced on the pipe fittings.

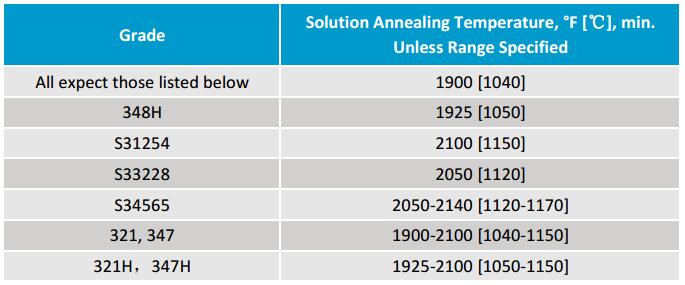

Heat treatment

For H grade steel, separate solution heat treatment are required for solution annealing. All pipe fittings should be supplied in heat treated condition. All welding work should be done before heat treatment. Fitting that have been machined directly from solution annealed forgings and bar stocks do not need to be annealed again.

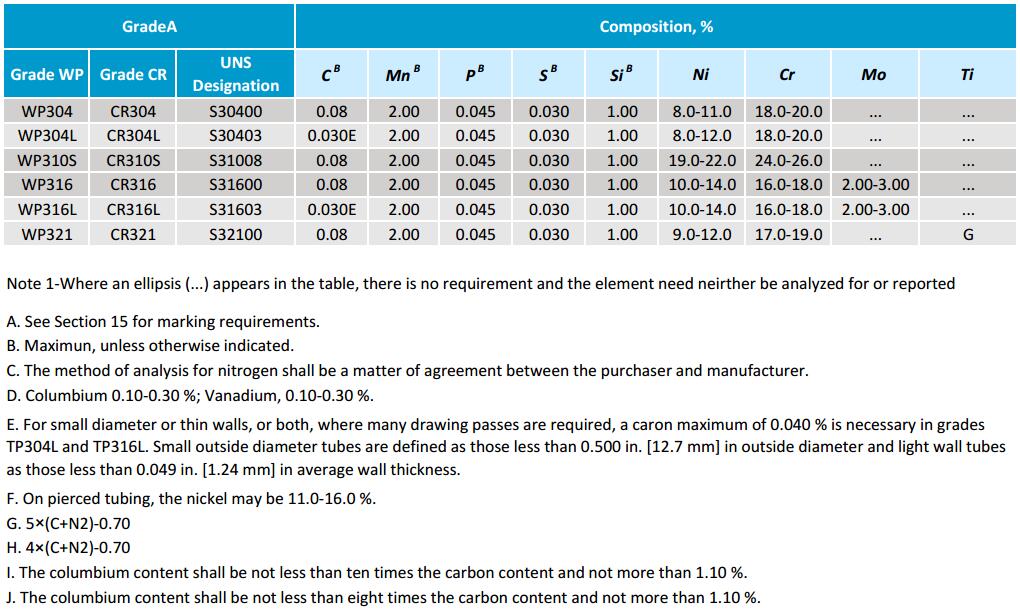

Chemical Composition

The chemical composition of each cast or furnace steel shall be determined and shall comply with the chemical composition requirements for each grade of material listed in the chemical composition table.

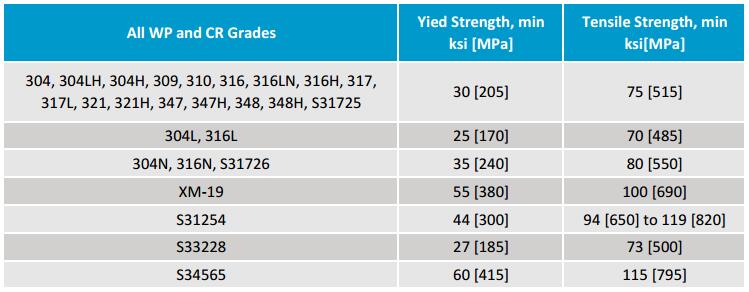

Tensile Properties

The tensile properties of the pipe fitting materials shall comply with the tensile properties requirements. Tests and reports shall be conducted in accordance with A370 methods and definitions.

For tensile testing, longitudinal or transverse cut specimens should be acceptable. Although tensile properties Table specifies the elongation requirements for the longitudinal and transverse specimens, it is not intended to be applicable at the same time. Instead, This intent that only the corresponding elongation requirements for specimens that are applicable in the direction are appropriate.

Tensile test report made on the starting material shall notes:

• The starting material report shall demonstrate that the properties of the pipe fittings material meet the requirements of this standard, provided that the heat treatment of the initial material is the same as that of the pipe fittings material.

• If the initial material has not been tested, or if the heat treatment of the initial material is different from that of the pipe fittings, the fitting manufacturer shall conduct at least one tensile test per furnace steel on the material representing of the finished pipe fittings, and the heat treatment condition shall be the same as that of the pipe fittings represented.

Surface Finish

Pipe fittings supplied in accordance with this standard shall be visually inspected. The depth of a typical surface discontinuity should be measured.

• Surface crack (fish scales) deeper than 1/64 inch (0.4 mm) should be removed.

• Mechanical flaws deeper than 1/16 inch (1.6 mm) should be removed.

• Except for the above two, the pipe fittings shall not have a surface discontinuity deeper than 5% of the specified nominal wall thickness, and shall have a good machined surface.

Repair by Welding Allowance

• When the defect depth exceeds 33 1/3 % of the nominal wall thickness, or the defect area exceeds 10% of the surface area of the pipe fitting, weld repair is not allowed under any circumstances.

• Unacceptable defects should be removed by mechanical means or by thermal cutting or gouging methods.

• Pipe fittings shall be free of scale and shall be passivated.

Octal supplies ASTM A403 Stainless Steel Pipe Fittings with Stock and Fresh New

Material Grade WP304/L, WP316/L, types in Elbow, Tee, Reducer, Cap and etc.